One of the things I’ve really enjoyed during my various visits to Japan is exploring its varied speciality coffee scene. There’s a strong, local tradition of roasting high-quality coffee, with an emphasis on darker roasts, epitomised by the likes of Maruyama Coffee and Sarutahiko Coffee Ebisu. However, in recent years, there’s an up-and-coming local scene where the emphasis is on lighter roasters led by the likes of today’s Meet the Roaster, Onibus Coffee.

One of the things I’ve really enjoyed during my various visits to Japan is exploring its varied speciality coffee scene. There’s a strong, local tradition of roasting high-quality coffee, with an emphasis on darker roasts, epitomised by the likes of Maruyama Coffee and Sarutahiko Coffee Ebisu. However, in recent years, there’s an up-and-coming local scene where the emphasis is on lighter roasters led by the likes of today’s Meet the Roaster, Onibus Coffee.

Onibus Coffee is a small coffee shop/roaster chain in Tokyo. Its Nakameguro location was one of my first stops when I came to Japan in 2017, my first time in the country. Back then, it also housed the roaster, in a small space behind the counter, but with the business steadily growing, the cramped conditions were proving impractical, so Onibus relocated the roastery to a new, dedicated coffee shop/roastery in Meguro.

I visited the coffee shop in September, on the first of this year’s two trips to Japan, where I was offered a tour of the roastery, scheduled for my returned in November. I gratefully accepted, heading over to the roastery in Yakumo on my first morning in Tokyo, where head roaster, Yohei, showed me around.

You can read more of my thoughts after the gallery.

Approaching Onibus that Sunday morning, I was greeted by the smell of roasting coffee wafting down the street. Onibus is set back a little, coffee shop on the right, roastery on the left, the new 22 kg Probat roaster clearly visible through the floor-to-ceiling windows. The coffee shop opened in May this year, with the roastery following in August, although the Probat, which was installed at the time, isn’t currently in use, and is expected to enter operation at the start of next year (2020).

The roastery isn’t open to the public, although you can watch through the windows if you like. It’s also clearly visible through the (much narrower) windows along the left-hand side of the coffee shop. Before starting my tour, I had a quick espresso, the barista recommending the Guatemalan single-origin. Never one to argue with a barista, I was rewarded with a smooth, well-balanced shot, although there was a hit of acidity on the first sip, after which it calmed down. Coffee out of the way, I was taken through to the roastery to meet Yohei.

As well as the new Probat, Onibus also has a smaller, 12 kg Diedrich, the original production roaster from the Nakameguro roastery. Tucked away at the back, behind the Probat on the left-hand side, the plan is to run the two machines together once the Probat comes into operation. To the right, a long counter runs along the windows between the roastery and coffee shop. This is where the coffee is bagged up, either in retail or wholesale bags, before being shipped out.

The final part of the roastery is off to the right, behind the counter in the coffee shop (but only accessible from the roastery). This is a temperature- and humidity-controlled stockroom, where Onibus stores its green beans. A far cry from the original space in Nakameguro, which was cramped and hot, the entire roastery occupying about as much space as the stockroom! The roastery is even more of a contrast, with so much space in comparison to Nakameguro.

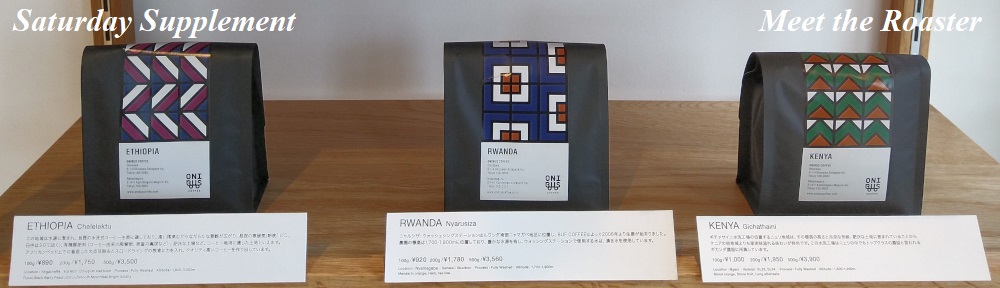

Onibus roasts every morning except Monday. There are five seasonal single-origins, with the coffee being bought a year ahead, the specific beans changing every six months. Although Onibus uses an importer to handle logistics, the staff visit every farm that they buy from, sourcing from a small selection of South/Central American and African producers.

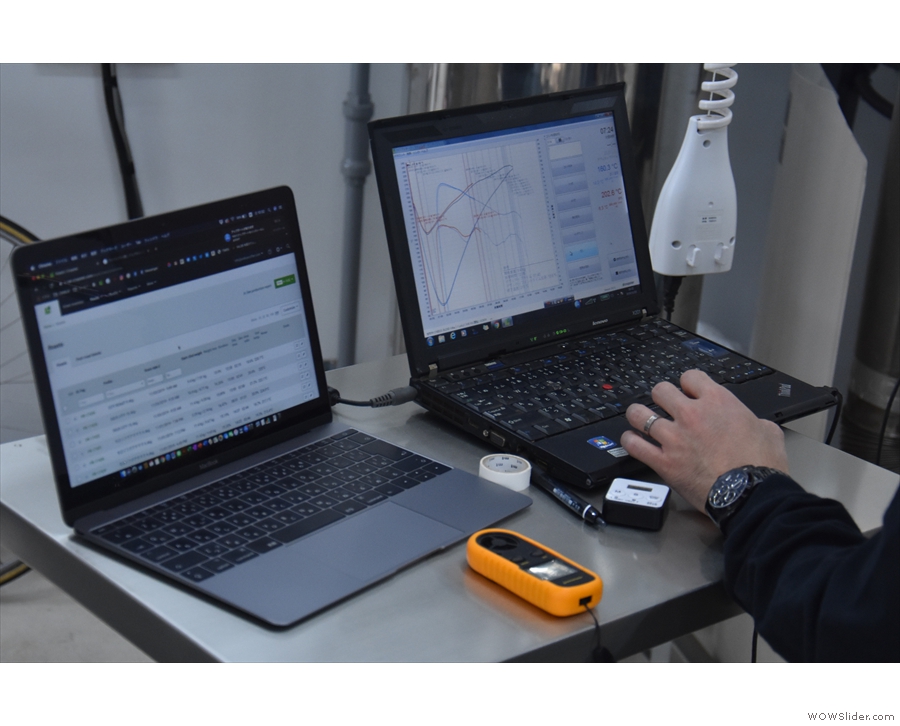

Yohei was roasting components of the Onibus Blend (different from the Step Blend served in the shop). This has two naturals (Brazil and Ethiopia) and a washed Guatemalan. Each competent is roasted separately, then combined in the cooling pan to form the finished blend.

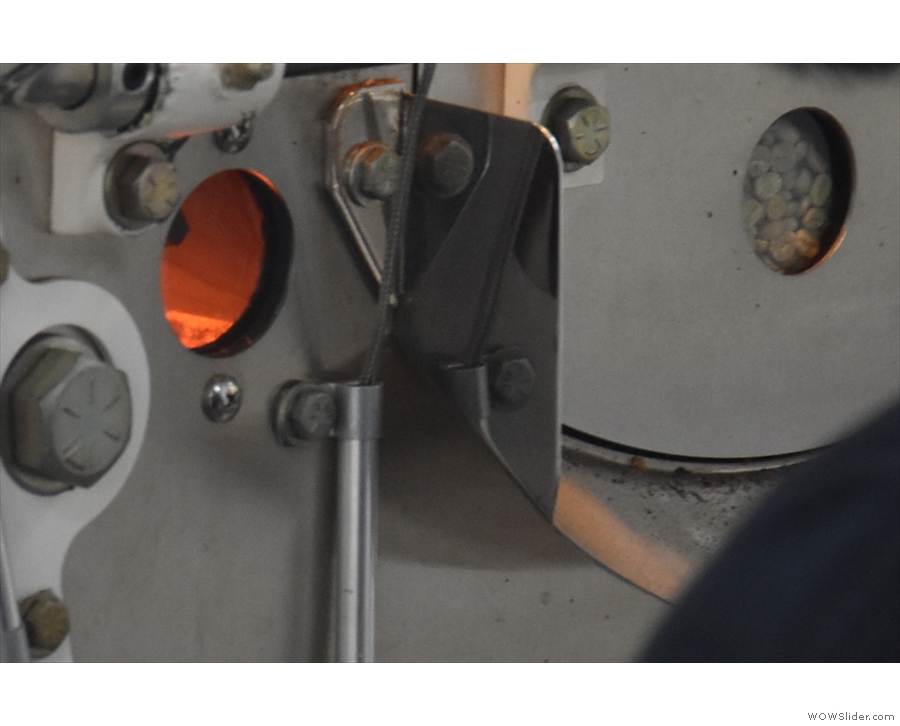

As I’ve mentioned, Onibus roasts light. The beans had barely gone beyond first crack when Yohei opened the flap on the roaster, sending the beans tumbling into the cooling pan. In fact, they were still popping as they came out, a rather magical sound! While the beans cool, Yohei sorts through them by hand, picking out any defects and unevenly roasted beans. These are put to one side, weighed and the results noted down. He also takes a sample of each roast for quality assurance. Finally, before bagging, the beans go through a destoning machine (no-one is going to thank a roaster who lets a stone through with their beans: a stone in a bag can ruin an expensive set of grinder burrs!).

In all, I spent a fascinating hour in the roastery, observing and chatting with Yohei. I’m very grateful to him and to Onibus for their time and patience. It was the perfect start to my time in Tokyo!

December 2019: Onibus Coffee was a runner-up for the 2019 Best Roaster/Retailer Award.

| 4-10-20 YAKUMO • MEGURO-KU • TOKYO • 152-0023 • JAPAN | ||||

| www.onibuscoffee.com | +81 (0) 3-5701-9349 | |||

| Monday | 09:00 – 18:00 | Roaster | Onibus (espresso + filter) | |

| Tuesday | 09:00 – 18:00 | Seating | Tables, Benches | |

| Wednesday | 09:00 – 18:00 | Food | Cake | |

| Thursday | 09:00 – 18:00 | Service | Order at Counter | |

| Friday | 09:00 – 18:00 | Payment | Cards + Cash | |

| Saturday | 09:00 – 18:00 | Wifi | Free | |

| Sunday | 09:00 – 18:00 | Power | Yes | |

| Chain | Local | Visits | 3rd November 2019 | |

Liked this Coffee Spot? Then check out the rest of Tokyo’s speciality coffee scene with the Coffee Spot Guide to Tokyo.

If you liked this post, please let me know by clicking the “Like” button. If you have a WordPress account and you don’t mind everyone knowing that you liked this post, you can use the “Like this” button right at the bottom instead. [bawlu_buttons]

Don’t forget that you can share this post with your friends using the buttons below.

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35 36

36 37

37 38

38 39

39 40

40 41

41 42

42

Pingback: Onibus Coffee, Yakumo | Brian's Coffee Spot

Pingback: Tandem Coffee Roasters | Brian's Coffee Spot

Pingback: Onibus Coffee, Nakameguro | Brian's Coffee Spot

Pingback: About Life Coffee Brewers | Brian's Coffee Spot